手 机:18803265188

电 话:0316-2318558

传 真:0316-2360318

邮 箱:thch1658@126.com

粉碎机组

文章来源: 更新时间:2018-11-15

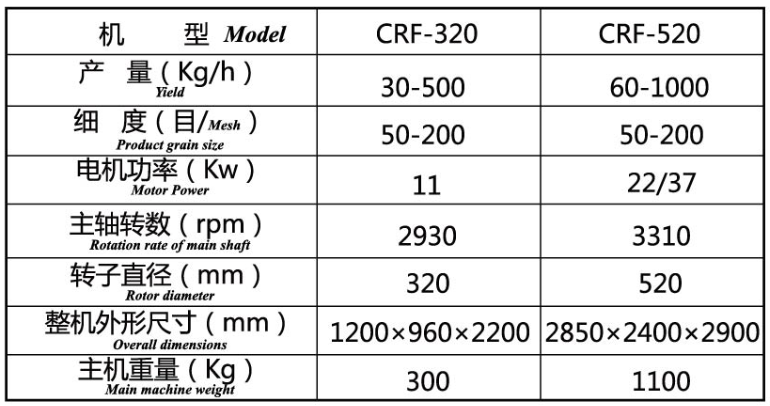

CRF系列粉粹机组是消化吸收了国际先进技术,结合实际情况研制成功的涡流式粉碎机。该机具有微粒小,温升小等特点。机组由粉碎主机、微粉收集器、布袋收集器、输送管道、电气控制柜及离心风机组成。物料在主机内部停留时间短,可防止过度粉碎及-陛能稳定,噪音低,耗电省、生产率高、造型美观等特点。是实拍、医药、化工、涂料、农药等行业理想的微细粉碎设备。

工作原理

本机采用了涡流的高速旋转运动,在粉碎室内产生了强大的气流。物料在负压下由进料口被吸入粉碎室,在叶片与模块间强大的气流作用下,产生冲击、剪切和研磨,由气流将粉碎室的热量带走,是粉碎过程中产生的热量不会急剧升温。成品物料从筛网流出,提高生产率,粉碎细度可由筛网的目数自行调节,成品细度均匀稳定。

CRF series splintered unit is absorbing the international advanced technology, combined with the actual situation in the successful development of the vortex mill. The machine has a small particulates, temperature and other characteristics. Crushed by the host unit, powder collector, bag collectors, pipelines, electrical control cabinet and centrifugal fan components. Material in the short residence time inside the host, to prevent excessive crushing and - Pi stable, low noise, low power consumption, high productivity, handsome in appearance and other characteristics. Is ideal for real shot, pharmaceutical, chemical, paint, pesticides and other industries fine grinding equipment.

Works

The machine uses a high-speed rotating vortex motion in the grinding room had a strong airflow. Material in the negative pressure is sucked into the feed opening crushing chamber between the blade and the module in the powerful airflow, an impact, shearing and grinding, the grinding chamber by a stream of the heat away, the heat generated during the grinding not rapid warming. Finished material flowing from the screen, increase productivity, grinding fineness mesh sieve by self-regulation, product fineness uniform and stable.